The structural integrity of any building relies heavily on its roof system, with roof trusses serving as the critical framework that supports the entire roofing structure. Property owners seeking durable, long-lasting buildings increasingly turn to metal components for their superior performance characteristics compared to traditional wood alternatives.

Metal structural elements provide unique strength-to-weight ratios while resisting common issues that plague wooden components, such as warping, rotting, and pest infestation. Understanding how these engineered systems contribute to building performance helps property owners make informed decisions about construction methods that impact their investment for decades to come.

Structural Superiority Through Advanced Engineered Truss Systems

The engineering principles behind Metal Roof Trusses create remarkable structural advantages that enhance building performance across various applications. Foremost Buildings Inc. in Jefferson, Wisconsin, specializes in designing and installing custom metal truss systems explicitly engineered for Wisconsin weather conditions. Their approach combines precise engineering calculations with quality materials to create roof structures that provide decades of reliable performance while accommodating the unique requirements of each building project.

Load Distribution Capabilities for Enhanced Structural Integrity

Metal roof trusses excel at evenly distributing weight loads throughout the building structure. This efficient load transfer minimizes stress concentrations that can compromise structural integrity over time, which is particularly important in regions with significant snow accumulation, like Wisconsin.

The geometric design of trusses creates triangulated sections that naturally distribute forces along the length of each member rather than concentrating pressure at specific points. This principle allows properly designed metal trusses to support substantial loads despite their relatively lightweight construction. The engineering precision possible with steel components ensures consistent performance across identical trusses within a building.

Precision Manufacturing for Consistent Quality

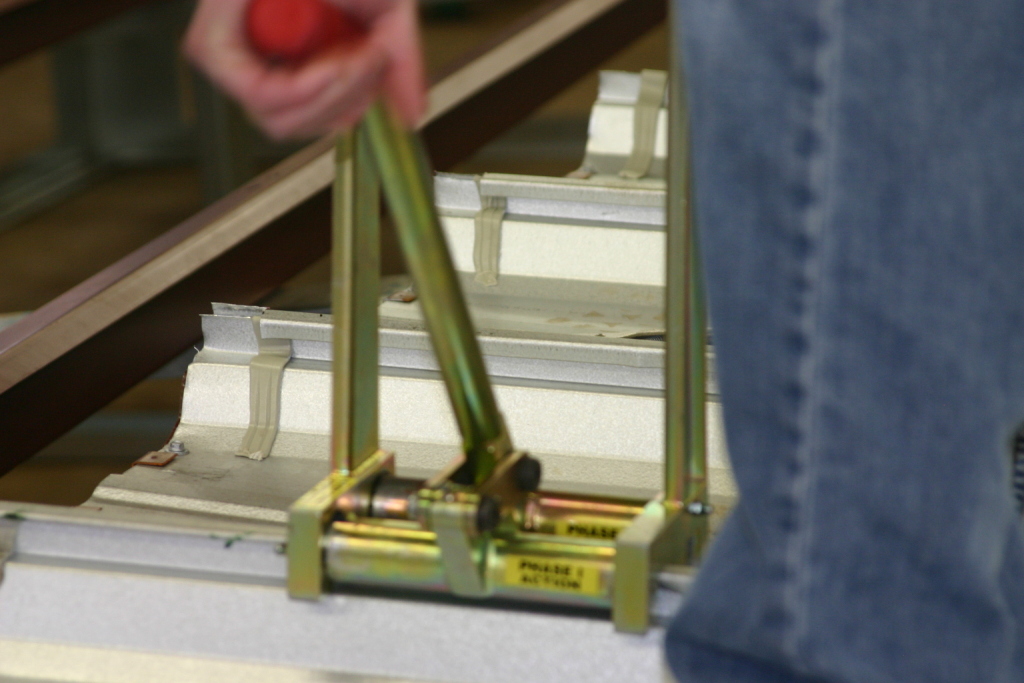

Modern metal roof trusses benefit from computer-aided design and manufacturing processes that ensure precise dimensions and consistent quality across every component. This manufacturing precision eliminates the natural variations inherent in wooden building materials.

The controlled production environment results in trusses with exact specifications that arrive at the construction site ready for installation. This consistency translates to predictable structural performance and simpler installation processes. Foremost Buildings Inc. leverages these manufacturing advantages to provide clients with reliable, high-performance truss systems that always meet engineered specifications.

Environmental Considerations and Sustainability Factors

Steel components used in metal roof trusses typically contain significant recycled content and remain utterly recyclable at the end of their useful life. This recycling potential reduces the environmental impact compared to materials that eventually enter landfills.

The durability and longevity of metal trusses also represent important sustainability factors by reducing the need for replacement and associated resource consumption. Buildings with longer service lives distribute their embodied carbon over more years of use, improving their environmental performance metrics. For environmentally conscious property owners, these characteristics align with sustainability objectives.

Design Flexibility for Architectural Expression

Modern metal truss systems accommodate diverse architectural styles and design requirements. From simple gable structures to complex multi-pitch configurations, metal trusses support creative architectural expression while maintaining structural integrity.

Metal’s engineering capabilities allow for innovative roof profiles that might be challenging or impossible with traditional framing methods. This design flexibility enables architects and builders to create distinctive buildings that serve both practical and aesthetic purposes. Foremost Buildings Inc. works closely with clients to balance design aspirations with structural performance requirements in every project.

Economic Benefits Through Construction Efficiency

Metal roof trusses typically enable faster construction timelines than traditional framing methods. Their prefabricated nature allows for rapid installation once they are delivered to the building site, reducing labor costs and overall construction time.

Precision manufacturing also minimizes material waste during installation, contributing to overall project efficiency. For commercial projects where time equals money, these efficiency advantages translate to earlier occupancy and faster returns on building investments. The combination of installation speed and long-term durability creates compelling economic benefits for property owners.

Conclusion

Metal roof trusses offer numerous significant advantages that enhance both the immediate construction process and the long-term performance of buildings. Their structural superiority, durability, and design flexibility make them an excellent choice for property owners seeking quality construction that will stand the test of time.

The investment in quality metal truss systems pays dividends through extended building lifespan, reduced maintenance requirements, and improved structural performance. By working with experienced metal building professionals who understand the engineering principles and practical applications of these systems, property owners can create structures that serve their needs reliably for generations while maintaining their structural integrity against the challenges of time and weather. Contact us today to schedule a consultation and take the first step toward a future-proof structure.

FAQ’s

Are metal roof trusses more expensive than wooden trusses?

Although metal roof trusses may cost more initially than wooden alternatives, the total lifecycle cost often proves lower when considering longevity, reduced maintenance, potential insurance savings, and the elimination of future repairs or replacements. The precise cost comparison depends on specific project requirements, market conditions, and local material availability. Many property owners find the long-term value proposition compelling despite higher upfront expenses.

How do metal roof trusses perform during extreme weather events?

When engineered adequately for local conditions, metal roof trusses show superior performance during extreme weather events. Their strength and ductility allow them to withstand high winds better than wooden alternatives. Steel’s consistent performance characteristics enable precise engineering calculations that account for maximum anticipated loads from snow, wind, or seismic events. This predictability provides more significant safety margins during severe weather conditions.

Can existing buildings be retrofitted with metal roof trusses?

Retrofitting existing buildings with metal roof trusses is possible during significant renovation projects, though the process requires careful structural engineering evaluation. Steel trusses’ lighter weight compared to their load capacity sometimes makes them suitable retrofit options without requiring foundation reinforcement. Each retrofit situation requires a professional assessment to determine feasibility and structural compatibility with the existing building systems.